UASB reactor – Upflow Anaerobic Sludge Blanket process

Upflow Anaerobic Sludge Blanket (UASB) reactor is the most widely used anaerobic technology for the biological treatment of industrial effluents.

Known for its compact design, low energy consumption, and ability to handle high organic loads, the UASB process offers a cost-effective solution for treating industrial wastewater from sectors such as food processing, breweries, pulp and paper production.

How it works:

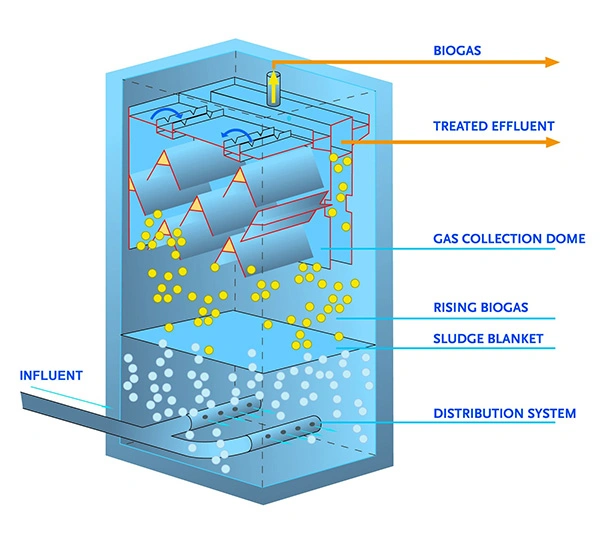

- The wastewater enters at the bottom of the reactor and flows upward through a granular sludge blanket, which contains anaerobic microorganisms, that decompose organic pollutants present in the wastewater.

- As the wastewater moves through the sludge bed, bacteria degrade organic matter, generating biogas primarily composed of methane (CH4) and carbon dioxide (CO2). The produced biogas rises and is collected at the top of the reactor.

- At the top, a phase separator helps to separate the gas from the liquid phase. The treated liquid exits the reactor at the top, while the biogas is directed to a gas collection system.

- The solid biomass (sludge) is retained in the reactor, continuously being recycled, which promotes efficient treatment.

Key characteristics:

- The system operates under anaerobic conditions, meaning it does not require oxygen, making it energy-efficient and effective for high-strength wastewater.

- Maximum process stability thanks to its controlled external re-circulation flow, which operates independently of the influent COD or flow rate.

- The UASB process operates under complete overpressure conditions, eliminating the need for an external biogas holder.

- The phase separators are made entirely of polypropylene (PP), ensuring durability, and eliminating corrosion risks.

- The phase separators utilize the mammoth stream principle that significantly improves the separation of solids and liquids, leading to better overall reactor performance.

- No complex internals such as tilted plates or rotating equipment, the system ensures maintenance-free operation with no risk of clogging.

- The UASB reactor can manage high loading rates, typically ranged between 5-15 kg COD/m³/day, making it ideal for efficiently treating high organic loads.