ECSB reactor – Advanced two-stage anaerobic process

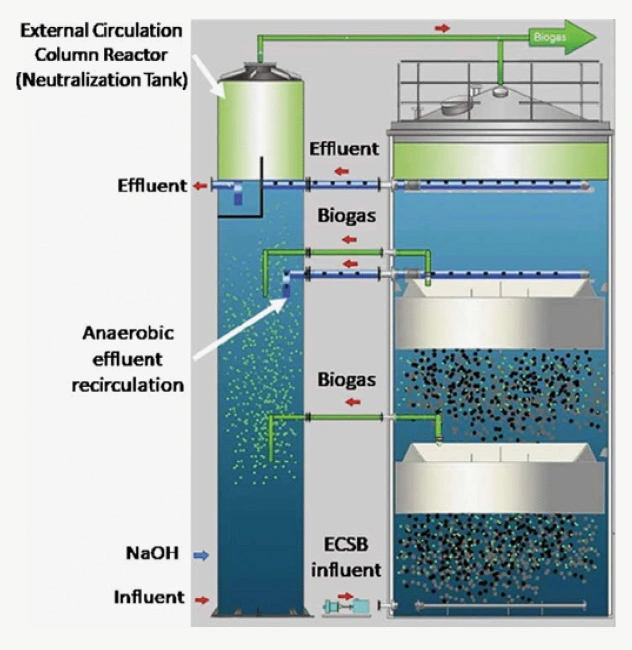

External Circulation Sludge Bed (ECSB) reactor is a two-stage anaerobic high-rate, process, the 3rd generation of EGSB systems, that has demonstrated its success across various industries worldwide (beverage, breweries, dairies, chemical processing).

Thanks to its two-stage design, this advanced system separates the produced biogas and biomass, achieving excellent biomass retention at high loads with maximum efficiency and operation stability.

How it works:

- The wastewater enters the ECSB reactor from the bottom via a special Distribution System and exits at the top, after passing through two phase separators that separate biogas from biomass.

- The lower reactor section contains a concentrated expanded sludge bed where pollutants are converted into biogas.

- The middle section allows smaller granular biomass to settle while a small amount of biogas is removed.

- Above the top phase separator, the water’s velocity is reduced, allowing for water recycling before effluent treatment.

- The collected biogas is sent to a neutralization tank, and excess biomass can be easily removed from the ECSB process.

Key characteristics:

- Manages high organic loads while minimizing space requirements.

- Ensures stable operation under varying load conditions for consistent treatment performance.

- Specially developed Influent Distribution System ensures even wastewater distribution, improving treatment efficiency and preventing sludge loss.

- The system operates under controlled biogas pressure, eliminating the need for an external gas holder and ensuring energy efficiency.

- Fully enclosed system with no odour emission points, ensuring an environmentally friendly operation.

- No special start-up requirements.

- No complex internals, making the system easier to operate and maintain.

- Safe and low maintenance