Biogas from Wastewater : Manage waste and generate energy

In today’s world, industries are under increasing pressure to adopt sustainable solutions that minimize environmental impact and optimize resource use.

One of the most promising solutions is the production of biogas from wastewater – a process that not only reduces environmental impact but also creates a valuable energy resource.

Industries such as breweries, dairies, beverage production, pulp and paper, and chemical manufacturing are leading the way, utilizing advanced technologies such as anaerobic reactors and solid waste digestion to transform waste into a valuable resource.

Let’s take a quick look at how this works!

What is biogas from wastewater?

Biogas is a mixture of gases produced during the breakdown of organic matter in the absence of oxygen. It primarily consists of methane (CH4) (50–75%) and carbon dioxide (CO2) (25–50%), with trace amounts of other gases like hydrogen sulfide (H2S) and nitrogen (N2).

Methane, the main component of biogas, is a potent energy source that can be used for electricity generation, heating, and even as a vehicle fuel.

The potential of industrial wastewater for biogas production

Industrial wastewater typically contains a high level of organic matter, which makes it a suitable resource for biogas production.

By utilizing anaerobic digestion, industries can convert this waste into biogas – a renewable energy source composed primarily of methane (CH4) and carbon dioxide (CO2).

This process not only provides a sustainable energy solution but also helps industries meet regulatory requirements for wastewater treatment and reduce operational costs.

Steps in biogas production:

- Hydrolysis: Complex organic compounds (e.g., fats, proteins, carbohydrates) are broken down into simpler molecules like sugars and amino acids.

- Acidogenesis: Acid-forming bacteria convert these simpler molecules into volatile fatty acids, alcohols, and gases like CO2 and H2.

- Acetogenesis: Acetogenic bacteria further break down the products into acetic acid, hydrogen, and CO2.

- Methanogenesis: Methanogenic bacteria convert acetic acid and hydrogen into methane and CO2.

How it works

The process of generating biogas from industrial wastewater involves two key components: anaerobic reactors and solid waste digestion.

Anaerobic reactors

The most widely used systems are the Upflow Anaerobic Sludge Blanket (UASB) reactor and the External Circulation Sludge Bed (ECSB) reactor. While both systems operate on similar principles, they have distinct differences in design, performance, and applications.

UASB reactor

Anaerobic granular sludge bed technology refers to a special kind of reactor concept for the “high rate” anaerobic treatment of wastewater.

High rate anaerobic treatment systems refer to bioreactors in which the sludge retention time (time for sludge biomass solids to pass through system) is separated from the hydraulic retention time (time for liquid to pass through system). The net effect is that slow growing anaerobes can be maintained in the reactor at high concentrations, enabling high volumetric conversion rates, while the wastewater rapidly passes through the reactor.

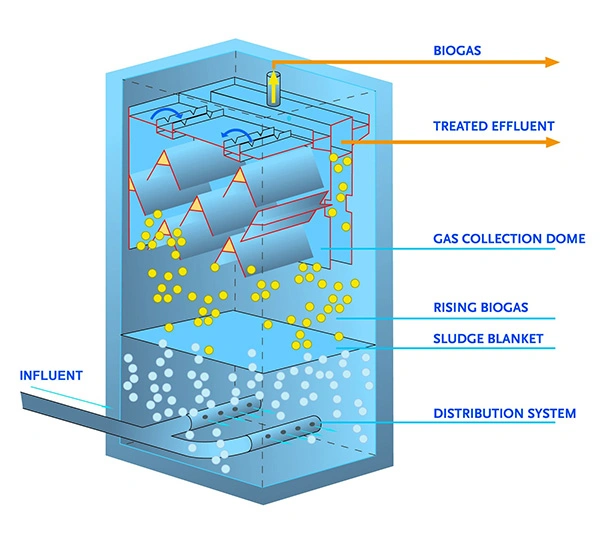

The concept was initiated with upward-flow anaerobic sludge blanket (UASB) reactor. A scheme of a UASB is shown below.

From a hardware perspective, a UASB reactor is at first appearance, nothing more than an empty tank (an extremely simple and inexpensive design).

The wastewater is entering at the bottom of the reactor, flowing upwards through a blanket of granular sludge. This sludge bed is where anaerobic microorganisms reside, breaking down organic pollutants in the wastewater.

As the wastewater rises through the sludge bed, bacteria in the sludge degrade the organic matter into biogas, primarily methane (CH4) and carbon dioxide (CO2). The produced biogas rises to the top of the reactor, where it is collected.

At the top, a phase separator helps to separate the gas from the liquid phase. The treated liquid exits the reactor at the top, while the biogas is directed to a gas collection system.

The solid biomass (sludge) is retained in the reactor, continuously being recycled, which promotes efficient treatment. The system operates under anaerobic conditions, meaning it does not require oxygen, making it energy-efficient and effective for high-strength wastewater.

Characteristics:

- Maximum process stability: the system maintains stable operation through controlled external re-circulation flow, making it independent of variations in influent COD and flow rates.

- Overpressure design: the UASB process operates under complete overpressure conditions, eliminating the need for an external biogas holder.

- Corrosion-resistant construction: phase separators are made entirely of polypropylene (PP), ensuring durability, and eliminating corrosion risks.

- Mammoth stream principle: this efficient design in the phase separators enhances solid-liquid separation and improve overall reactor performance.

- Simplified internal design: with no complex internals such as tilted plates or rotating equipment, the system ensures maintenance-free operation with no risk of clogging.

- High organic loading capacity: the UASB reactor can manage loading rates between 5-15 kg COD/m³/day, making it ideal for efficiently treating high organic loads.

ECSB reactor

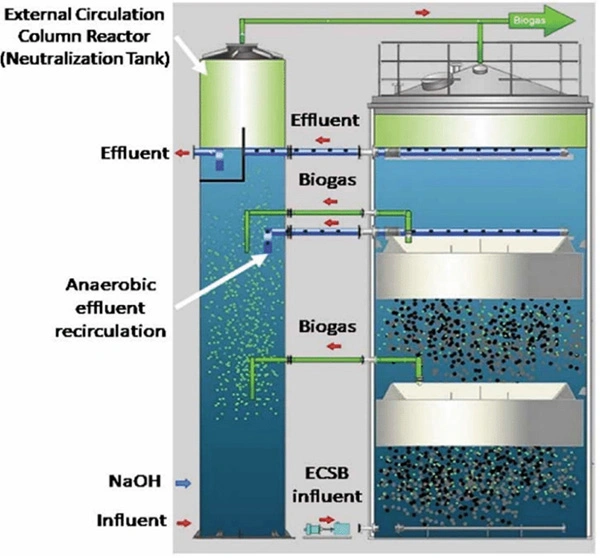

External Circulation Sludge Bed (ECSB) reactor is an advanced two-stage anaerobic high-rate process, the 3rd generation of EGSB systems, that has a proven success already in many different types of industries around the world.

Thanks to its two-stage design, this advanced system separates the produced biogas and biomass, achieving excellent biomass retention at high loads with maximum efficiency and operation stability.

The wastewater enters the ECSB reactor from the bottom via a special Distribution System and exits at the top, after passing through two phase separators that separate biogas from biomass.

The lower reactor section contains a concentrated expanded sludge bed where pollutants are converted into biogas, which is mostly separated from the biomass-water mixture. The middle section allows smaller granular biomass to settle while a small amount of biogas is removed.

Above the top phase separator, the water’s velocity is reduced, allowing for water recycling before effluent treatment. The process operates under biogas pressure, ensuring a closed system that eliminates odors and prevents corrosion. The collected biogas is sent to a neutralization tank, and excess biomass can be easily removed from the ECSB process.

Characteristics:

- Compact and highly efficient: manages high organic loads while minimizing space requirements, ensuring optimal space efficiency.

- Controlled hydraulic conditions: ensures stable operation under varying load conditions for consistent treatment performance.

- Specially developed Influent Distribution System: ensures even wastewater distribution, improving treatment efficiency and preventing sludge loss.

- Biogas overpressure operation: The system operates under controlled biogas pressure, eliminating the need for an external gas holder and ensuring energy efficiency.

- Odor-Free process: fully enclosed system with no odor emission points, ensuring an environmentally friendly operation.

- Easy Start-Up: no special start-up requirements, allowing for quick and straightforward commissioning.

- Simplified design: no complex internals, making the system easier to operate and maintain.

- Safe and low maintenance: engineered for long-term reliability with minimal operational intervention.

Applications:

- Breweries: wastewater from breweries contains high levels of organic compounds like sugars and starches, which are ideal for anaerobic digestion.

- Dairies: dairy wastewater is rich in fats, proteins, and lactose, making it a strong candidate for biogas production.

- Pulp and Paper: the organic content in wastewater from pulp and paper mills can be converted into biogas, reducing the environmental footprint of the industry.

- Chemical Manufacturing: even chemical-laden wastewater can be treated using specialized anaerobic reactors to recover energy.

Solid Waste Digestion:

In addition to wastewater, many industries generate solid organic waste, such as spent grains from breweries or sludge from dairy processing.

The Solid Waste Digestion (SWD) process utilizes advanced Continuous Stirred Tank Reactor (CSTR) technology offering an efficient and reliable solution for waste reduction and green energy production.

Our Solid Waste Digestion (SWD) process is very different from a common digester and is characterized by extreme high safety measures to never allow problems resulting from foaming, blockages of pipes and valves, while it carries special precautions against any condition that can jeopardize the system.

Characteristics:

- Completely mixed reactor design: offered in options with or without sludge separation and recycling to improve flexibility.

- Active anaerobic biomass suspension: mechanical mixing using top or side-entry mixers keeps the anaerobic biomass evenly suspended, ensuring optimal contact with organic material.

- Efficient COD conversion: both soluble and solid chemical oxygen demand (COD) are efficiently transformed into biogas, which is temporarily held in the reactor headspace for later use.

- Performs exceptionally well in industries with high levels of fats, oils, and greases, such as food processing and rendering facilities.

- Maintains strong performance in wastewater with high calcium levels, effectively preventing scaling problems.

- Capable of managing wastewater streams with high ammonia content, ensuring a stable and reliable anaerobic digestion process.

Benefits of biogas production from industrial wastewater

Biogas technology offers numerous advantages for industries:

- Renewable energy generation: biogas can be used to generate electricity, heat, or even upgraded to biomethane for use as vehicle fuel or injection into natural gas grids.

- Cost savings: by treating wastewater on-site and generating energy, industries can significantly reduce their utility bills and waste disposal costs.

- Environmental sustainability: biogas production reduces greenhouse gas emissions by capturing methane that would otherwise be released into the atmosphere. It also minimizes the discharge of pollutants into water bodies.

- Regulatory compliance: many industries face strict regulations for wastewater treatment. Anaerobic digestion helps meet these requirements while adding value through energy recovery.

- Circular economy contribution: by converting waste into energy, industries contribute to a circular economy, where waste is viewed as a resource rather than a liability.

For industries looking to reduce their environmental footprint, lower operational costs, and contribute to a sustainable future, biogas production from wastewater is a win-win solution.

If your industry is ready to explore the benefits of biogas, contact us today to learn how we can help you design and implement a customized wastewater-to-energy solution.